Microgreens Post-Harvest Processing: Protocols Ensuring Freshness and Food Safety

Harvesting microgreens takes skill and attention to detail. These tiny plants pack a lot of nutrients, but they need careful handling from the moment they’re cut until they reach someone’s plate. Getting it right can be the difference between selling top-quality greens that restaurants want and ending up with limp, potentially unsafe produce that no one can use.

Consider this: while growing microgreens requires careful attention, it’s the post-harvest practices—cutting, washing, drying, storing, and transporting—that ultimately determine whether they’ll reach consumers in their prime condition. A single misstep in temperature control or handling can transform weeks of careful cultivation into compromised product within hours.

| Critical Factor | Impact on Quality | Food Safety Risk | Best Practice |

| Temperature | Wilting at >40°F | Bacterial growth | Store at 35-38°F |

| Moisture | Decay if too wet | Mold development | Dry before storing |

| Handling | Bruising damage | Cross-contamination | Employ clean tools |

| Storage Time | Loss of nutrients | Pathogen multiplication | Consume within 7 days |

As your business grows, it demands a systematic approach—each step building upon the last like links in a chain. From precise harvesting techniques using sanitized tools to maintaining optimal humidity levels during storage, every detail matters. When executed properly, these protocols can extend shelf life from a mere week to an impressive 14-21 days while ensuring both safety and quality.

Professional growers understand this delicate balance, recognizing that success lies not just in growing these tender greens, but in mastering the critical window between harvest and consumption. Let’s explore how to navigate this crucial phase with precision and care.

Key Takeaways

- Store microgreens at precise temperatures between 35-38°F with 95% relative humidity to maximize freshness and prevent wilting.

- Use clean, sharp stainless steel tools for harvesting and cut just above soil line to avoid contamination.

- Implement proper drying techniques using gentle air circulation or clean towels to prevent pathogen growth.

- Package microgreens in ventilated, food-grade containers with adequate airflow to maintain optimal moisture levels.

- Monitor daily for signs of spoilage including discoloration, mold, off-odors, and changes in texture.

Microgreens need specific conditions to stay fresh and safe. Like most perishable produce, they’re sensitive to their environment – but even more so because they’re so small and delicate.

Temperature control is key. You want to keep them between 35-40°F (1-4°C), with 38°F working best for most types. Go warmer than that and they’ll start to wilt pretty quickly. If they freeze, you’ll end up with mushy, dark leaves that no one wants to eat.

Humidity matters just as much. These greens need high humidity – around 95-100% – to stay crisp. But here’s the catch: while they need moisture in the air, you don’t want water sitting on the leaves. That’s just asking for mold and bacteria to move in. Professional growers achieve this delicate balance through:

| Environmental Factor | Target Range | Monitoring Method | Warning Signs |

| Temperature | 35-40°F (1-4°C) | Digital thermometers | Condensation, wilting |

| Humidity | 95-100% RH | Hygrometers | Dry edges, soggy leaves |

| Air Circulation | Gentle flow | Visual inspection | Stagnant moisture, mold |

Good airflow is the last piece of the storage puzzle. You need steady, gentle movement to keep the air fresh, but not so much that it stresses out the greens. The goal is to avoid dead spots where moisture could build up.

Smart growers keep careful records of all these conditions. Think of it like taking vital signs – your logs tell you if everything’s running right or if something needs fixing.

Digital monitoring systems can provide real-time alerts when conditions drift from optimal ranges, allowing for swift corrections before quality suffers.

These environmental controls aren’t just numbers on a thermometer—they’re the fundamental rhythm that keeps your microgreens dancing from harvest to plate. Master these elements, and you’ve mastered the foundation of post-harvest success.

The Harvesting Process

Picture this: It’s early morning in your microgreens facility, and the first rays of light streaming thru the window in front of you reveal trays of vibrant shoots standing at attention, their tiny leaves glistening with the last traces of moisture. This moment—the harvest—is where art meets science in the world of microgreen cultivation.

Timing transforms an ordinary harvest into an extraordinary one. The sweet spot arrives when microgreens reach 2-3 inches in height and display their first true leaves. Depending on the variety, typically between days 10-21 after sowing. Like a chef who knows exactly when to pull bread from the oven, experienced growers recognize their crops’ peak moment through both measurement and intuition.

Tool Selection & Preparation

| Essential Equipment | Purpose | Maintenance Schedule |

| Stainless Steel Scissors | Clean cutting, minimal damage | Sanitize before each harvest |

| Food-Grade Gloves | Contamination prevention | Change between batches |

| Sanitized Containers | Safe collection and transport | Clean daily, inspect before use |

| Digital Thermometer | Temperature monitoring | Calibrate weekly |

Harvesting microgreens is pretty straightforward, but you need to do it right. Use clean, sharp stainless steel scissors and cut just above the soil line. Cut too high and you’re wasting good product. Too low and you risk getting soil in with your greens, which isn’t safe.

Signs of Perfect Harvest Readiness:

- Uniform height across the tray (2-3 inches)

- Well-developed cotyledons alongside first true leaves

- Stems showing appropriate thickness for variety

- Vibrant, characteristic coloring

- Crisp, upright stance

The process demands more than just technical precision—it requires a gentle touch. Harvested microgreens should be handled as minimally as possible, treated more like delicate flower petals than conventional produce. Each movement should be deliberate, each cut precise, as bruising or rough handling can trigger early deterioration.

Temperature control begins the moment stems are severed. Within 30 minutes of harvest, microgreens should enter their cooling journey, transitioning gradually to storage temperatures to prevent shock. Think of it as helping them ease into a gentle slumber rather than throwing them into a cold plunge.

A perfect harvest sets the stage for everything that follows. Like a foundation for a house, careful attention here supports every subsequent step in the post-harvest process. Master these fundamentals, and you’re well on your way to consistently exceptional microgreens.

There’s an ancient debate in the world of microgreens that rivals the intensity of whether to wash mushrooms: to wash or not to wash? Like many age-old questions in food production, the answer lies not in absolutes but in understanding the delicate dance between safety and quality.

Let’s pull back the curtain on this crucial decision. While washing can remove surface contaminants and debris, it introduces moisture—potentially our tender greens’ greatest vulnerability. Think of microgreens like fine silk; once water enters the equation, handling becomes infinitely more complex.

When Washing Is Necessary:

| Method | Temperature | Duration | Key Considerations |

| Cool Water Bath | 33-35°F | 1-2 minutes | Gentle agitation only |

| Spray Washing | 33-35°F | 30 seconds | Low pressure, even coverage |

| Sanitizing Solution | 33-35°F | Per product specs | FDA-approved only |

For commercial growers, the washing protocol often includes food-grade sanitizers, each with its own steps:

| Sanitizer Type | Concentration | Contact Time | Notes |

| Chlorine | 50-200 ppm | 1-2 min | pH 6.5-7.5 required |

| Peroxyacetic Acid | 30-80 ppm | 45 sec | No pH adjustment needed |

| Citric Acid | 1-3% solution | 5 min | Organic-approved option |

But here’s where the story takes an interesting turn—the drying process becomes just as crucial as the washing itself. Picture a delicate balancing act between removing excess moisture while preserving the greens’ tender structure. Commercial operations often employ gentle air circulation systems, while smaller producers might opt for food-grade centrifugal spinners.

When it comes to drying, think of it less as a race and more as a gentle transition. Too aggressive, and you’ll damage the delicate leaves; too passive, and you’re inviting unwanted microbial growth. The sweet spot lies in achieving that perfect state where moisture has departed but vitality remains—like morning dew evaporating from flower petals.

For those who choose not to wash, the focus shifts to prevention: maintaining pristine growing conditions, using elevated growing systems to prevent soil contact, and implementing strict handling protocols. After all, the cleanest microgreen is one that never needed washing in the first place.

Whether washing or not, the goal remains the same—delivering safe, vibrant microgreens to eager plates. Like a chef selecting the perfect preparation method for a prized ingredient, your choice should align with your scale of operation, target market, and ability to maintain consistent quality control.

Storage and Transportation Systems

Storing and moving microgreens takes careful planning. The packaging needs to protect these delicate greens while showing off how fresh they are. Most importantly, you need to maintain the right temperature, humidity, and airflow the whole time – from harvest to delivery.

The Container Conundrum

Think of storage containers as more than just vessels—they’re specialized environments that can either nurture or compromise your harvest. Professional growers face a fascinating choice between two main characters in this story: rigid clamshells and breathable bags. Each writes its own chapter in the tale of freshness:

| Container Type | Advantages | Limitations | Best Uses |

| Clamshells | Superior physical protection, stackable | Limited air exchange | Short-distance transport |

| Breathable Bags | Optimal gas exchange, moisture control | Less structural protection | Longer-term storage |

| Modified Atmosphere | Extended shelf life, reduced respiration | Higher cost, technical expertise needed | Commercial operations |

But here’s where the plot thickens—it’s not just about choosing the right container. The real artistry lies in understanding how these vessels interact with their precious cargo. Professional growers have learned that leaving small gaps between containers allows for that crucial breath of air circulation, like giving each plant its own personal space in a crowded room.

The Transportation Tale

Moving microgreens is all about managing temperature and sticking to a schedule. It’s really just two main things:

| Critical Factor | Target Range | Monitoring Method | Emergency Response |

| Temperature | 34-40°F | Digital loggers | Backup cooling ready |

| Humidity | 95-100% RH | Humidity sensors | Moisture packets available |

| Stack Height | Maximum 3 layers | Visual checks | Immediate restacking if shifted |

The smart approach is to plan your route and timing carefully. Think about when temperatures are lowest and traffic is lightest – usually early morning is your best bet.

Each delivery run is different, and success comes down to being ready for things to go wrong. You need backup plans and quick fixes when conditions aren’t perfect, which happens more often than you’d think.

Think of quality control as the invisible guardian of your microgreen operation—a sophisticated dance of prevention, monitoring, and quick response that transforms good intentions into consistent excellence. Like a master chef’s mise en place, proper food safety protocols create the foundation for everything that follows.

Let’s peel back the layers of what makes a truly robust safety system. It’s not just about following rules—it’s about creating a culture where safety becomes as natural as breathing, where every team member moves through their day with the precise awareness of a surgeon in an operating room.

The Pillars of Food Safety

| Documentation | Purpose | Frequency | Critical Points |

| Cleaning Logs | Track sanitation | Daily | Tools, surfaces, containers |

| Temperature Records | Monitor storage | Every 4 hours | Walk-ins, transport units |

| Staff Training | Ensure compliance | Monthly | Handling procedures, updates |

| Batch Tracking | Enable traceability | Every harvest | Seed to sale documentation |

But here’s where science meets storytelling—successful operations don’t just maintain records, they read them like a detective novel, looking for patterns and potential problems before they emerge. Think of each log entry as a chapter in an ongoing narrative about your operation’s health.

The Human Element

Even the most sophisticated safety protocols depend on the people implementing them. Consider these fundamental practices that transform abstract guidelines into daily habits:

- Handwashing becomes a ritual, not just a requirement

- Tool sanitization flows naturally between tasks

- Cross-contamination prevention guides every movement

- Documentation becomes second nature

Here’s what separates good operations from great ones: they understand that food safety isn’t just about preventing problems—it’s about building trust. Each carefully monitored temperature reading, each properly documented cleaning session, each trained team member contributes to a larger story of reliability and excellence.

In the world of microgreens, quality control isn’t just a department or a checklist—it’s the invisible thread that weaves through every aspect of your operation, from the moment seeds touch soil to the final handoff to eager customers. Each crop step must play its part perfectly to create something truly exceptional.

Monitoring and Troubleshooting

Every microgreen grower learns this truth eventually: even with perfect protocols, challenges arise. Like a detective piecing together clues, successful growers develop a sixth sense for spotting potential issues before they become problems. It’s not just about maintaining quality—it’s about reading the subtle language your plants speak.

Let’s explore the art and science of keeping your microgreens thriving from harvest to plate. Think of it as becoming fluent in a new language, where every yellowing leaf, every drop of condensation, every subtle change in texture tells a story.

The Warning Signs

| Common Issue | Early Indicators | Root Causes | Quick Response |

| Wilting | Leaf droop, loss of shine | Temperature fluctuation, moisture loss | Adjust humidity, verify cooling |

| Yellowing | Color fade, spotting | Age, temperature stress | Check storage conditions |

| Mold Growth | White fuzz, musty odor | Excess moisture, poor airflow | Improve ventilation, isolate affected product |

| Texture Changes | Softening, sliminess | Bacterial growth, aging | Remove affected portions, verify temperature |

But here’s where experience transforms into wisdom: the best growers don’t just react to problems—they anticipate them. Like a chess master thinking several moves ahead, they recognize that today’s minor temperature fluctuation could become tomorrow’s quality crisis.

Prevention Through Observation

Consider implementing this daily check sequence:

- Morning inspection of overnight storage conditions

- Midday monitoring of active harvests and processing

- Evening verification of all environmental controls

- Spot checks of random containers throughout the day

Think of these regular checks as taking your operation’s pulse—they tell you whether everything’s running smoothly or if intervention might be needed. The key lies not just in collecting data but in understanding its story. A slight temperature drift might not spell immediate disaster, but it could signal equipment beginning to falter.

When problems do arise, approach them with curiosity rather than frustration. Each challenge offers a lesson, a chance to strengthen your systems. Like a scientist conducting experiments, document what works and what doesn’t. Your future self will thank you for the detailed notes that help prevent history from repeating.

Problems aren’t failures—they’re opportunities to deepen your understanding and refine your processes. Success lies not in avoiding all challenges but in building the knowledge and systems to address them swiftly and effectively.

Think of a successful microgreens operation as a living, breathing ecosystem where efficiency flows not just from machinery and protocols, but from the accumulated wisdom of countless harvests. Like ancient farmers who learned to read the stars, today’s growers have developed their own sophisticated ways of understanding their craft.

The Dance of Scale and Quality

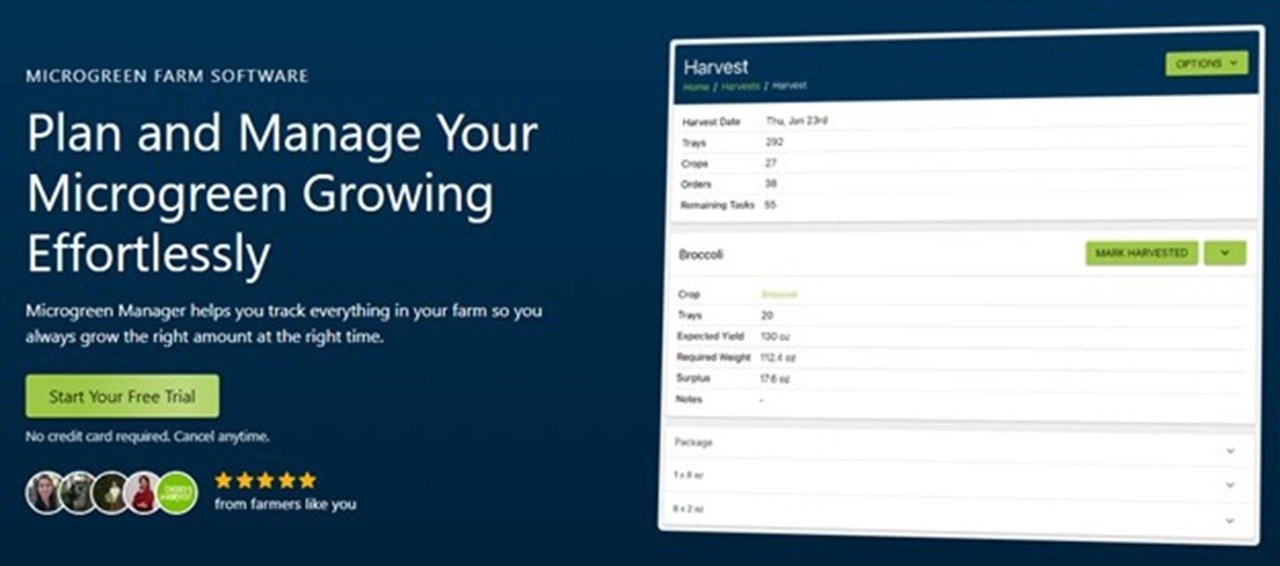

The journey from small-scale producer to commercial powerhouse isn’t just about getting bigger—it’s about getting smarter. Consider the story of Piedmont Microgreens, where owner Garrett Corwin transformed a garage startup into a thriving urban farm. His secret? Understanding that growth isn’t just about space—it’s about systems.

| Efficiency Metrics | Small Scale | Medium Scale | Large Scale |

| Daily Harvest (sq ft) | 10-20 | 50-100 | 200+ |

| Labor Hours/lb | 1.5-2 | 0.8-1.2 | 0.3-0.5 |

| Waste Percentage | 15-20% | 8-12% | 3-7% |

| Storage Capacity (days) | 3-5 | 5-7 | 7-14 |

But here’s where the story gets interesting: the most successful operations don’t just scale up—they scale smart. They understand that every touch point is an opportunity for improvement or an invitation for error. Like a well-choreographed dance, each movement must have purpose.

Wisdom from the Field

The most valuable lessons often come from those who’ve walked the path before:

- Implement a “touch-point reduction” system to minimize handling

- Create zones for different activities to prevent cross-contamination

- Pre-weigh packaging materials to streamline processing

- Maintain detailed production logs to track yields and identify patterns

Think of these practices not as rigid rules but as guideposts on your journey to excellence. Each operation writes its own story, finds its own rhythm. What works for a urban rooftop garden might need adaptation for a rural greenhouse operation.

Perhaps most importantly, successful growers understand that their true product isn’t just microgreens—it’s trust. Every carefully harvested tray, every properly stored container, every on-time delivery builds that precious commodity one small step at a time.

Your success isn’t just measured in pounds or dollars—it’s measured in relationships built, standards maintained, and promises kept. Like any craft pursued with passion and precision, growing microgreens commercially becomes not just a business, but a calling.

Related Questions

Can Microgreens Regrow After Being Cut for Harvest?

Most microgreens cannot regrow after harvesting as they are typically cut at the stem near soil level. Unlike mature plants, microgreens lack the developed root system and growth points necessary for regeneration.

How Do Different Growing Mediums Affect the Final Taste of Microgreens?

Growing mediums significantly influence microgreens’ taste. Soil typically produces earthier flavors, while hydroponic systems yield cleaner tastes. Coconut coir creates balanced flavors, and peat-based mediums can impart subtle mineral notes.

Are Some Microgreen Varieties Naturally More Resistant to Bacterial Contamination?

Research indicates certain microgreen varieties like mustard and arugula contain natural antimicrobial compounds that provide increased resistance to bacterial contamination. However, scientific studies are still ongoing to fully understand these protective mechanisms.

Do Colored LED Lights Impact the Nutritional Content of Microgreens?

Research indicates that different LED light colors can significantly affect microgreens’ nutritional content. Red and blue lights typically improve antioxidant levels, while specific wavelength combinations can increase vitamin content and phytochemical production.

What Causes Some Microgreens to Develop Bitter Flavors During Storage?

Microgreens can develop bitter flavors during storage due to enzymatic changes, oxidation, temperature fluctuations, and ethylene exposure. These processes trigger chemical reactions that produce bitter compounds as the plant tissue breaks down.

Like any worthwhile journey, the path from seed to sale in microgreen cultivation tells a story far richer than its individual steps might suggest. Think of what we’ve explored as a tapestry, where each thread—from precise temperature control to thoughtful handling—weaves together to create something greater than its parts.

The success of your microgreens operation ultimately rests not just in following protocols, but in understanding the deeper rhythms that govern this delicate dance. It’s about recognizing that every decision, from the moment you make that first cut to the final handoff to an eager chef, ripples through the entire system.

Key Elements for Success:

| Practice | Impact | Legacy |

| Temperature Control | Immediate quality preservation | Consistent reputation |

| Handling Protocols | Daily safety assurance | Customer trust |

| Documentation | Current traceability | Operational wisdom |

| Staff Training | Present efficiency | Cultural excellence |

But perhaps the most profound lesson lies in understanding that mastering microgreen production is less about achieving perfection and more about embracing continuous improvement. Like a chef who never stops refining their signature dish, successful growers remain eternally curious, eternally vigilant, eternally open to learning.

Every tray of vibrant microgreens that reaches its destination in peak condition represents more than just successful crop management—it represents a promise kept, a standard maintained, a reputation strengthened. In the end, we’re not just growing plants; we’re cultivating trust, building a business, one delicate leaf at a time.

The future of microgreen cultivation lies not just in maintaining these standards but in pushing them forward, always asking how we might do better, grow better, serve better. After all, in this living, breathing art form we call microgreen production, there’s always another lesson to learn, another process to refine, another horizon to explore.

What story will your next harvest tell?

References

The references listed below represent a selection of key recent patents consulted in the creation of this article on microgreens post-harvest processing. They provide valuable insights into the food safety considerations associated with microgreen production and consumption.

Abaajeh, A. R., Kingston, C. E., & Harty, M. (2023). Environmental factors influencing the growth and pathogenicity of microgreens bound for the market: a review. Renewable Agriculture and Food Systems, 38, e12. https://doi.org/10.1017/S174217052300008X

Amitrano, C., Paglialunga, G., Battistelli, A., Veronica De Micco, Marta Del Bianco, Liuzzi, G., Moscatello, S., Paradiso, R., Proietti, S., Youssef Rouphael, & Stefania De Pascale. (2023). Defining growth requirements of microgreens in space cultivation via biomass production, morpho-anatomical and nutritional traits analysis. Frontiers in Plant Science, 14. https://doi.org/10.3389/fpls.2023.1190945

Dubey, S., Harbourne, N., Harty, M., Hurley, D., & Elliott-Kingston, C. (2024). Microgreens Production: Exploiting Environmental and Cultural Factors for Enhanced Agronomical Benefits. Plants, 13(18), 2631. https://doi.org/10.3390/plants13182631

Mason, S. A., et al. (2016). “Vitamin C supplementation improves insulin sensitivity in people with type 2 diabetes.” Indian Journal of Medical Research, vol. 144, no. 4, pp. 508-514. https://dom-pubs.onlinelibrary.wiley.com/doi/abs/10.1111/dom.13571

Pinow, L. S. (2024). Smart control of indoor microgreens growing environment. Handle.net. http://hdl.handle.net/10198/30234

Polash, M. A. S., Sakil, M. A., & Hossain, M. A. (2018). Post-harvest biodegradation of bioactive substances and antioxidant activity in microgreens. Journal of the Bangladesh Agricultural University, 16(2), 250–253. https://doi.org/10.3329/jbau.v16i2.37975

Renna, M., & Paradiso, V. M. (2020). Ongoing research on microgreens: Nutritional properties, shelf-life, sustainable production, innovative growing and processing approaches. Foods, 9(6), 826. https://doi.org/10.3390/foods9060826

Resh, H. M. (2015). Hydroponics for the home grower. CRC Press.

Sharma, A., Mainu Hazarika, Punabati Heisnam, Pandey, H., V.S. Devadas, Singh, D., Mannu Wangsu, & Kartha, B. D. (2023). Influence of storage conditions, packaging, post-harvest technology, nanotechnology and molecular approaches on shelf life of microgreens. Journal of Agriculture and Food Research, 14, 100835–100835. https://doi.org/10.1016/j.jafr.2023.100835

Sıla BARUT GÖK, Fatma ÖZDÜVEN, & Funda ERYILMAZ AÇIKGÖZ. (2023). Effect of Different Harvest Times on Phenolic Content and Antioxidant Activity of Some Microgreens. Kahramanmaraş Sütçü İmam University Journal of Agriculture and Nature. https://doi.org/10.18016/ksutarimdoga.vi.1216114